2. 广西农垦金光乳业有限公司, 南宁 530001;

3. 广西畜牧研究所, 南宁 530002

2. Guangxi Nongken Jinguang Dairy Co., Ltd., Nanning 530001, China;

3. Guangxi Institute of Animal Science, Nanning 530002, China

我国地域辽阔,饲料资源丰富、种类繁多,其中某些粗饲料由于所含养分极不平衡、适口性差等因素,不宜作为饲粮中唯一粗饲料来源的饲料原料。在无法对这类饲料进行营养价值的直接评定时可利用套算法对这类粗饲料进行养分表观消化率测定[1-2]。甘蔗副产物甘蔗渣中由于含有大量的木质纤维,直接饲喂会影响动物采食量及瘤胃消化。国内外的研究指出,甘蔗渣经过碱化处理或高温蒸汽爆破处理制成的碱化蔗渣(alkalized sugarcane bagasse,ASB)或膨化蔗渣(steam explosion sugarcane bagasse,SESB)可以改善瘤胃降解性[3-4]。在相关研究中,王世琴等[5]利用半体内法测定了甘蔗尾叶的降解率;Ahemd等[6]和Freitas等[7]也使用半体内法测定了甘蔗渣的降解率,但均未对甘蔗尾叶青贮(sugarcane tops silage,SS)及甘蔗渣的养分表观消化率进行测定。在查阅文献和饲养标准时尚未发现有关甘蔗尾叶青贮、碱化蔗渣、膨化蔗渣养分表观消化率的相关数据。因此,本研究旨在应用套算法结合内源指示剂法在西门塔尔牛上测定甘蔗尾叶青贮、碱化蔗渣、膨化蔗渣的养分表观消化率,为科学利用甘蔗副产物提供参考。

1 材料与方法 1.1 试验原料甘蔗尾叶青贮、膨化蔗渣和碱化蔗渣均由广西农垦绿姆山牛场提供。甘蔗尾叶青贮制备:将新鲜甘蔗尾叶切碎后按2 mL/kg喷洒含有植物乳杆菌(活菌数7.70×107 CFU/mL)和枯草芽孢杆菌(活菌数1.20×108 CFU/mL)的混合菌液(体积比2 : 1)后,转移至干净的青贮池压实覆膜青贮,甘蔗尾叶青贮90 d后用于后续试验。膨化蔗渣制备:将干物质含量为50%的甘蔗渣使用温度为220~250 ℃、压力为20 kg/cm2的膨化罐处理4 min,将处理后的甘蔗渣放置于干净的青贮池内常温储存120 d后用于后续试验。碱化蔗渣制备:采用干物质含量为50%的甘蔗渣按12 g/kg添加氢氧化钠(NaOH),并用混合机混匀后放置于干净的青贮池内,常温保存90 d后用于后续试验。粗饲料营养水平见表 1。

|

|

表 1 粗饲料营养水平 Table 1 Nutrient levels of the roughage |

试验采用内源指示法测定养分表观消化率,通过套算法交叉试验设计测定甘蔗副产物的养分表观消化率。试验1:测定甘蔗尾叶青贮的养分表观消化率,分为试验Ⅰ期和试验Ⅱ期,试验Ⅰ期组1饲喂以象草(elephant grass,EG)为粗饲料的全混合日粮(TMR),组2饲喂以30%(干物质基础)的甘蔗尾叶青贮饲粮替换象草的TMR;试验Ⅱ期组1饲喂以30%(干物质基础)的甘蔗尾叶青贮替换象草的TMR,组2饲喂以象草为粗饲料的TMR,每期持续14 d,包括9 d的预试期和5 d的正试期,整个试验共计28 d。碱化蔗渣(试验2)和膨化蔗渣(试验3)试验设计同甘蔗尾叶青贮,试验设计详见表 2。

|

|

表 2 试验设计 Table 2 Test design |

试验选取约1周岁、体重350 kg左右的体况良好的西门塔尔牛36头,分为6个组,每组6个重复,每个重复1头牛,单栏单饲,自由采食和饮水。试验在广西农垦绿姆山牛场进行。TMR组成及各组TMR营养水平见表 3和表 4。

|

|

表 3 全混合日粮组成(风干基础) Table 3 Composition of TMR (air-dry basis) |

|

|

表 4 各组TMR营养水平 Table 4 Nutrient levels of TMR for each group |

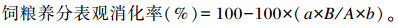

试验采用内源指示剂法(盐酸不溶灰分法)测定饲粮养分表观消化率。于试验正式开始后进行粪样采集工作(收粪持续5 d),每头牛每天分别在08:00和14:30通过直肠各采集100 g新鲜粪样,共计200 g新鲜粪样,然后加入20 mL浓度为10%的硫酸进行固氮后保存(-20 ℃),同时采集各组饲粮样本500 g。饲粮养分表观消化率计算公式如下:

|

式中:A为饲粮中某养分的含量(%);a为粪样中某养分的含量(%);B为饲粮中指示剂的含量(%);b为粪样中指示剂的含量(%)。

1.4 常规营养成分的测定分别将每头牛每天的粪样混合,于烘箱中65 ℃烘干至恒重,再将5 d的粪样或饲粮样混合均匀后粉碎过40目筛,干燥保存待测。饲粮和粪样中的干物质(GB/T 6435—2014)、盐酸不溶灰分(GB/T 23742—2009)和粗灰分(Ash)含量(GB/T 6438—2007)进行测定;采用滤袋法(ANKOM-200美国)测定中性洗涤纤维(NDF)和酸性洗涤纤维(ADF)含量;粗蛋白质(CP)含量使用凯氏定氮仪(Gerhart Vapodest 50s,德国)测定;总能(GE)使用氧弹式量热仪(Sundy SDC5015,长沙)测定。

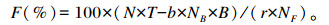

1.5 数据分析试验数据先经Excel 2010初步处理。参考董国忠[8]描述的内源指示剂法结合套算法计算甘蔗尾叶青贮、碱化蔗渣和膨化蔗渣的养分表观消化率,计算公式如下:

|

式中:F为被测饲料养分表观消化率;N为被测饲粮养分含量;T为被测饲粮养分表观消化率;b为被测饲粮中基础饲粮占的比例;NB为基础饲粮养分含量;B为基础饲粮中养分表观消化率;r为被测饲粮中被测饲料的占比;NF为被测饲料养分含量。

使用SPSS 19.0软件进行单因素方差分析,采用Duncan氏法进行多重比较,P < 0.05表示差异显著。结果用平均值表示,各组变异程度用均值标准误(SEM)表示。

2 结果由表 5中饲粮养分表观消化率经套算法公式计算得到表 6中甘蔗副产物的养分表观消化率。甘蔗尾叶青贮、碱化蔗渣和膨化蔗渣的干物质表观消化率分别为83.18%、59.74%和62.22%,有机物表观消化率分别为74.74%、58.96%和61.56%,总能表观消化率分别为70.98%、59.61%和62.72%,粗蛋白质表观消化率分别为66.93%、12.16%和15.69%,中性洗涤纤维表观消化率分别为47.47%、32.65%和38.28%,酸性洗涤纤维表观消化率分别为33.77%、25.70%和22.04%。甘蔗尾叶青贮的干物质、有机物、粗蛋白质、中性洗涤纤维、酸性洗涤纤维和总能表观消化率显著高于碱化蔗渣和膨化蔗渣(P<0.05),膨化蔗渣的粗蛋白质和中性洗涤纤维表观消化率显著高于碱化蔗渣(P<0.05),膨化蔗渣的酸性洗涤纤维表观消化率显著低于碱化蔗渣(P<0.05)。

|

|

表 5 饲粮养分表观消化率 Table 5 Dietary nutrient apparent digestibility |

|

|

表 6 甘蔗副产物的养分表观消化率 Table 6 Nutrient apparent digestibility of sugarcane by-products |

由表 5中饲粮养分表观消化率与表 1中3种粗饲料营养水平可以计算得到表 7中甘蔗副产物的消化能和可消化粗蛋白质含量。甘蔗尾叶青贮的消化能和可消化粗蛋白质含量分别为12.78 MJ/kg和5.21%,碱化蔗渣的消化能和可消化粗蛋白质含量分别为10.14 MJ/kg和0.21%,膨化蔗渣的消化能和可消化粗蛋白质含量分别为10.76 MJ/kg和0.33%。

|

|

表 7 甘蔗副产物的消化能和可消化粗蛋白质含量 Table 7 Digestible energy and digestible crude protein content of sugarcane by-products |

套算法又称顶替法,通过配制基础饲粮和按一定比例替代基础饲粮的待测饲粮,先经过消化试验测定待测饲粮和基础饲粮的养分表观消化率,然后再根据2种饲粮的养分表观消化率,计算待测饲料原料的养分表观消化率。套算法适用于测定某些不能单一饲喂的饲料原料表观消化率,如各类谷实或粗饲料。甘蔗渣含有38%~45%的纤维素,26%~25%的半纤维素和20%~30%的木质素[9-11],因此,不宜作为单一的饲料原料饲喂动物来测定表观消化率。有关套算法用于评定粗饲料的报道中,李冲等[1]在家兔上对比直接法和套算法测定养分表观消化率,结果显示这2种方法测定的干物质、粗蛋白质、粗纤维、中性洗涤纤维和酸性洗涤纤维表观消化率差异不显著;赵明明等[2]比较套算法和插值法估测花生秧的有效能值时指出:套算法可用于评估花生秧的消化能和代谢能。全收粪法是一种理想的收粪方法,但在没有消化代谢笼时粪样易受尿液污染,收粪不及时可能导致养分表观消化率的测定不准确,且收粪量过多、处理困难。因此,本研究采用内源指示剂法结合套算法测定含甘蔗副产物饲粮的养分表观消化率。

De Almeida等[12]发现当奶牛饲粮中甘蔗渣的添加水平从45%增加到60%时,干物质、有机物、粗蛋白质和中性洗涤纤维表观消化率呈线性下降。在Freitas等[7]最近的研究中,饲粮的干物质表观消化率随饲粮中甘蔗渣的添加水平线性下降,这与De Almeida等[12]的研究结果一致。结合De Almeida等[12]和Freitas等[7]的研究以及套算法中建议的待测饲料原料添加比例,本试验添加30%(干物质基础)的甘蔗渣替换象草测定养分表观消化率。在本试验中,膨化蔗渣的粗蛋白质和中性洗涤纤维表观消化率显著高于碱化蔗渣,碱化蔗渣和膨化蔗渣的总能表观消化率和消化能分别为59.61%和10.14 MJ/kg、62.72%和10.76 MJ/kg,表明膨化处理甘蔗渣优于碱化处理甘蔗渣。

唐振华等[13]研究指出,生长水牛采食甘蔗尾叶青贮与玉米青贮相比不影响饲粮干物质、有机物、酸性洗涤纤维和中性洗涤纤维的表观消化率。周雄等[14]通过饲粮中100%甘蔗尾叶青贮替代羊草饲喂海南黑山羊,测得饲粮粗蛋白质、中性洗涤纤维和酸性洗涤纤维的表观消化率分别为70.90%、59.54%和56.03%。Suliman等[15]通过40~45 kg的Osimi×Chios羊测得饲喂甘蔗尾叶青贮的饲粮干物质、有机物和粗蛋白质的表观消化率分别为64.79%、65.14%和62.12%。在本试验中,通过套算法计算甘蔗尾叶青贮的干物质、有机物、粗蛋白质、中性洗涤纤维、酸性洗涤纤维和总能的表观消化率分别为83.18%、74.74%、66.93%、47.47%、33.77%、70.98%,甘蔗尾叶青贮总能表观消化率和消化能分别为70.98%和12.78 MJ/kg。

综上所述,甘蔗尾叶青贮是甘蔗副产物中最佳的粗饲料,不同的甘蔗渣处理方式中膨化蔗渣优于碱化蔗渣。

4 结论① 甘蔗副产物中甘蔗尾叶青贮的养分表观消化率、消化能及可消化粗蛋白质含量最高,是甘蔗副产物中最佳的粗饲料。

② 不同的甘蔗渣处理方式中膨化蔗渣的饲用价值优于碱化蔗渣。

| [1] |

李冲, 吴峰洋, 陈宝江, 等. 套算法与直接法测定家兔饲料表观消化率的对比分析[J]. 饲料研究, 2017(15): 18-23, 30. |

| [2] |

赵明明, 马涛, 赵江波, 等. 花生秧作为肉用绵羊单一粗饲料有效能值的测定与估测[J]. 动物营养学报, 2017, 29(11): 4162-4170. DOI:10.3969/j.issn.1006-267x.2017.11.040 |

| [3] |

AHMADI F, ZAMIRI M J, KHORVASH M, et al. Pre-treatment of sugarcane bagasse with a combination of sodium hydroxide and lime for improving the ruminal degradability:optimization of process parameters using response surface methodology[J]. Journal of Applied Animal Research, 2016, 44(1): 287-296. DOI:10.1080/09712119.2015.1031783 |

| [4] |

DE CASTRO F B, MACHADO P F. Feeding value of steam treated sugar cane bagasse in ruminant rations[J]. Livestock Research for Rural Development, 1990, 2(1): 47-49. |

| [5] |

王世琴, 张乃锋, 邓凯东, 等. 甘蔗梢对肉羊的饲用价值评定[J]. 动物营养学报, 2018, 30(3): 1146-1154. DOI:10.3969/j.issn.1006-267x.2018.03.040 |

| [6] |

AHEMD M H, BABIKER S A, FADEL ELSEED A E M A, et al. Effect of urea-treatment on nutritive value of sugarcane bagasse[J]. ARPN Journal of Science and Technology, 2013, 3(8): 834-838. |

| [7] |

FREITAS W R, DE ANDRADE FERREIRA M, SILVA J L, et al. Sugarcane bagasse as only roughage for crossbred lactating cows in semiarid regions[J]. Pesquisa Agropecuária Brasileira, 2018, 53(3): 386-393. DOI:10.1590/s0100-204x2018000300014 |

| [8] |

董国忠. 指示剂法和套算法计算饲料养分消化率公式的推导和应用[J]. 中国饲料, 1996(3): 31-32. |

| [9] |

RUDOLF A, BAUDEL H, ZACCHI G, et al. Simultaneous saccharification and fermentation of steam-pretreated bagasse using Saccharomyces cerevisiae TMB3400 and Pichia stipitis CBS6054[J]. Biotechnology and Bioengineering, 2008, 99(4): 783-790. DOI:10.1002/bit.21636 |

| [10] |

BEZERRA T L, RAGAUSKAS A J. A review of sugarcane bagasse for second-generation bioethanol and biopower production[J]. Biofuels, Bioproducts and Biorefining, 2016, 10(5): 634-647. DOI:10.1002/bbb.1662 |

| [11] |

CARVALHO A F A, MARCONDES W F, NETO P O, et al. The potential of tailoring the conditions of steam explosion to produce xylo-oligosaccharides from sugarcane bagasse[J]. Bioresource Technology, 2018, 250: 221-229. DOI:10.1016/j.biortech.2017.11.041 |

| [12] |

DE ALMEIDA G A P, DE ANDRADE FERREIRA M, DE LIMA SILVA J, et al. Sugarcane bagasse as exclusive roughage for dairy cows in smallholder livestock system[J]. Asian-Australasian Journal of Animal Sciences, 2018, 31(3): 379-385. DOI:10.5713/ajas.17.0205 |

| [13] |

唐振华, 周玲, 邹彩霞, 等. 青贮甘蔗尾、青贮玉米秸秆对生长水牛生长性能、消化代谢及血液生化指标的影响[J]. 中国畜牧兽医, 2016, 43(1): 92-100. |

| [14] |

周雄, 周璐丽, 王定发, 等. 日粮中青贮甘蔗尾叶替代不同比例王草对海南黑山羊生长性能、养分表观消化率及血清生化指标的影响[J]. 中国畜牧兽医, 2015, 42(6): 1443-1448. |

| [15] |

SULIMAN A I A, AZZA M M B, EBTEHAG I M. Performance of lambs fed on biologically treated silages[J]. International Journal of Chemistry Research, 2016, 9: 151-160. |