2. 辽宁康普利德生物科技有限公司, 铁岭 112600;

3. 辽宁省饲料预消化专业技术创新中心, 铁岭 112600

2. Liaoning Complete Biotechnology Co., Ltd., Tieling 112600, China;

3. Liaoning Feed Pre-Digested Technology Innovation Center, Tieling 112600, China

豆粕是优质的蛋白质饲料,广泛应用于动物生产中,但豆粕中含有的热敏性、热稳定性和抗维生素因子[1-2],会阻碍动物消化并引发免疫反应。因此,如何有效去除豆粕中的抗营养因子,引起了人们的广泛关注。研究表明,通过物理、化学、微生物和酶制剂法可有效消除抗营养因子[3-5]。研究发现,饲料经膨化后,能够显著提高猪养分全肠道表观消化率和必需氨基酸回肠表观消化率[6-8];膨化后的饲料颗粒淀粉糊化度得到提高,饲料的粉化率降低,从而能够提高肉兔对饲粮养分的表观消化率[9]。但膨化法去除的抗营养因子含量较低[10-11],且耐热抗营养因子,尤其是抗原蛋白质难以去除。因此,针对大豆抗营养因子使用酶,如利用蛋白酶、淀粉酶和碳水化合物酶等可去除饲料中耐高温的抗营养因子[12-14]。龚阿琼等[15]研究表明,在相同条件下,复合酶制剂对豆粕中抗原蛋白的降解效果优于单一酶制剂。魏凤仙等[16]和魏金涛等[17]比较了不同加工工艺处理的豆粕中的抗营养因子含量,表明酶解豆粕比膨化豆粕对大豆球蛋白和β-伴大豆球蛋白去除的效果更彻底,而去皮豆粕对大豆球蛋白基本没有去除作用。膨化和酶解作为豆粕的新兴加工工艺,在饲料生产中的应用很有研究价值,尤其是在饲料禁抗的大背景下,通过合理利用饲料原料加工带来的免疫性能优势,可降低动物死淘率,减少因禁抗带来的经济损失。因此,本试验旨在比较豆粕不同加工工艺(普通、膨化和酶解)对肉兔颗粒饲料加工特性、养分表观消化率和血清免疫指标的影响,为其在家兔生产中的合理应用提供科学依据。

1 材料与方法 1.1 试验材料试验使用的普通豆粕、膨化豆粕和酶解豆粕购自辽宁某生物科技有限公司。生产工艺如下:普通豆粕是大豆经浸提法提取豆油后得到的副产品;膨化豆粕是普通豆粕经140 ℃高温,短时膨化处理得到的产品;酶解豆粕是普通豆粕经组合酶预消化处理得到的低抗营养因子、高小肽含量的功能性蛋白质产品。

1.2 试验设计、试验动物和饲粮本试验采用单因素随机设计,依据DB37/T 1835—2011《肉兔饲养标准》配制5种饲粮,饲粮组成及营养水平见表 1。饲粮唯一变量是豆粕加工工艺,分别为10%普通豆粕(OS)、10%膨化豆粕(ES)、10%酶解豆粕(EhS)、5%普通豆粕+5%膨化豆粕(OES)和5%普通豆粕+5%酶解豆粕(OEhS),其余原料比例相同。为更好地反映不同加工工艺豆粕对肉兔作用效果的差异,设计豆粕在饲粮中的比例达10%,且饲粮粗蛋白质(CP)水平比饲养标准高出1.3个百分点。试验颗粒饲料在沈阳立得饲料有限公司制作完成。

|

|

表 1 饲粮组成及营养水平(风干基础) Table 1 Composition and nutrient levels of diets (air-dry basis) |

试验选取150只70日龄、平均体重为(1.78±0.13) kg的雄性伊拉肉兔(使用同一性别试验的目的是消除性别差异对试验结果的影响),随机分为5个组,每组15个重复,每个重复2只兔。5个组肉兔分别饲喂以上不同饲粮。试验期35 d。

1.3 试验动物的饲养管理饲养试验于2019年11月22日至2019年12月27日在沈阳农业大学兔试验基地进行。采用3层阶梯兔笼,每笼(60 cm×50 cm×40 cm)2只兔,每笼设置2个采食口和1个乳头饮水器。试验兔自由采食和饮水。舍内装备暖气,温度维持在18 ℃左右,相对湿度为60%~70%,每天自然光照或人工补光至12 h。

1.4 样品采集饲养试验结束时,每个组取5只体重接近平均体重的肉兔,颈静脉采血,存于10 mL抗凝管中,4 ℃、3 000×g离心15 min后,取上层血清,置于5 mL离心管中在20 ℃下保存待测。

1.5 检测指标及方法 1.5.1 颗粒饲料加工特性饲料制备完成后,采用四分法分别取颗粒饲料2 kg于自封袋中,依据张丽英[19]的方法测定颗粒饲料的加工品质,容重、含粉率和粉化率每个处理重复测3次。

硬度:每种饲粮随机选取10粒颗粒,使用GWJ-Ⅱ型谷物硬度计测量硬度,结果取平均值。

容重:在1 000 mL量筒中倒满饲料颗粒,将超出量筒上边缘的颗粒用直尺削平,然后称量量筒内所装饲料质量(E),E与量筒容积(V)之比即为容重。

含粉率:将试验样品用四分法分为2份,每份约500 g,放置在14目(2.0 mm)的金属筛中手动筛分,称量筛下物重量,筛下物重量占试验样品总重的百分比,即为含粉率。

粉化率:将测定含粉率之后的筛上物装入ST-136颗粒粉化率测定仪,箱体转500次停机以后取出,用14目金属筛手动筛分,称量筛下物重量,筛下物重量占试样总重的百分比,即为粉化率。

1.5.2 养分表观消化率由于试验兔日龄较大,实测各组生长性能无显著差异,因此本文没有列出生长性能的试验结果。在饲养试验最后4 d,每组选取5个笼(每笼2只兔),即5个重复,采用内源指示剂(盐酸不溶灰分,AIA)法进行消化试验,以笼为单位,每日收取部分粪样,喷洒少量10%浓度的盐酸(HCl)固氮。一部分鲜粪样品先使用105 ℃烘15 min灭菌,然后转到65 ℃烘至恒重,将烘干的样品在室内空气冷却回潮24 h,得到风干样品;另一部分鲜粪样品依据GB/T 6435—2014《饲料中水分的测定》,采用直接干燥法(105 ℃)测定干物质(DM)含量。

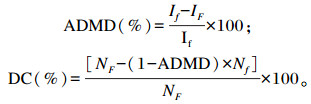

饲粮和粪的风干样品粉碎后,过40目筛,装入自封袋,阴凉处保存备用。饲粮和粪中的总能采用IKA C2000 basic量热仪测定,CP含量采用雷磁KDN-1凯氏定氮仪测定,中性洗涤纤维(NDF)和酸性洗涤纤维(ADF)含量采用ANKOM-2000纤维素分析仪测定,样品中的AIA含量参照GB/T 23742—2009《饲料中盐酸不溶灰分的测定》进行测定。养分表观消化率计算参照文献[20],计算公式如下:

|

式中:ADMD为饲粮DM表观消化率(%);DC为某养分表观消化率(%);IF为饲粮中AIA含量(%);If为粪样中AIA含量(%);NF为饲粮中某养分含量(%);Nf为粪样中某养分含量(%)。

1.5.3 血清免疫指标血清总蛋白(TP)和白蛋白(ALB)含量采用考马斯亮蓝比色法,按照总蛋白定量试剂盒和白蛋白试剂盒操作说明进行测定,并计算球蛋白(GLB)含量(总蛋白含量-白蛋白含量);血清免疫球蛋白A(IgA)、免疫球蛋白M(IgM)和免疫球蛋白G(IgG)及补体3(C3)和补体4(C4)含量采用酶联免疫吸附试验法,按照试剂盒操作说明,用Infinite M200 Pro酶标仪进行测定。试剂盒均购自江苏宝莱生物科技有限公司。

1.6 数据统计分析试验数据采用SPSS 23.0进行单因素方差分析,并使用Duncan氏法进行多重比较,P < 0.05为差异显著,结果用“平均值±标准差”以及均值标准误(SEM)表示。

2 结果 2.1 豆粕不同加工工艺对肉兔颗粒饲料加工特性的影响由表 2可知,OEhS组颗粒饲料硬度(53.83 N)显著高于其他各组(P < 0.05),分别比OS组、ES组、EhS组和OES组提高了108.64%、38.49%、96.46%和28.08%;EhS组颗粒饲料容重(1.04 kg/L)显著高于其他各组(P < 0.05),分别比OS组、ES组、OES组和OEhS组提高了10.64%、25.30%、7.22%和10.64%;EhS组颗粒饲料含粉率最低,但各组之间差异不显著(P>0.05);EhS组颗粒饲料粉化率(10.25%)显著高于其他各组(P < 0.05),OEhS组颗粒饲料粉化率最低(3.40%)。

|

|

表 2 豆粕不同加工工艺对肉兔颗粒饲料加工特性的影响 Table 2 Effects of different processing technologies of soybean meal on processing characteristics of pellet feed for meat rabbits |

由表 3可知,各组间肉兔DM表观消化率差异不显著(P>0.05);ES组和EhS组总能表观消化率显著高于OS组、OES组和OEhS组(P < 0.05);OES组CP表观消化率显著高于OS组、ES组和EhS组(P < 0.05),且OEhS组CP表观消化率显著高于OS组和ES组(P < 0.05);OEhS组NDF和ADF表观消化率显著高于ES组、EhS组和OES组(P < 0.05),同时OEhS组ADF表观消化率显著高于OS组(P < 0.05)。

|

|

表 3 豆粕不同加工工艺对肉兔养分表观消化率的影响 Table 3 Effects of different processing technologies of soybean meal on nutrient apparent digestibility of meat rabbits |

由表 4可知,OS组肉兔血清总蛋白含量显著高于其他各组(P < 0.05);OS组和OES组血清白蛋白含量分别为42.25和43.74 g/L,显著高于其他各组(P < 0.05);OS组血清球蛋白含量显著高于其他各组(P < 0.05),EhS组血清球蛋白含量显著低于其他组(P < 0.05)。

|

|

表 4 豆粕不同加工工艺对肉兔血清总蛋白、白蛋白和球蛋白含量的影响 Table 4 Effects of different processing technologies of soybean meal on contents of TP, ALB and GLB in serum of meat rabbits |

由表 5可知,OEhS组肉兔血清IgA含量显著低于EhS组和OES组(P < 0.05);OS组血清IgG含量显著高于EhS组和OEhS组(P < 0.05);EhS组血清C3含量最低,显著低于其他各组(P < 0.05);ES组血清C4含量显著高于OS组和OEhS组(P < 0.05)。

|

|

表 5 豆粕不同加工工艺对肉兔血清免疫球蛋白和补体含量的影响 Table 5 Effects of different processing technologies of soybean meal on contents of immunoglobulin and complement in serum of meat rabbits |

研究表明,在影响颗粒饲料制粒品质的各种因素中,配方是主要因素,影响占比高达40%[21],主要是因为配方中原料的理化特性影响饲料的制粒性能[22],这不仅包括原料种类,也包括对原料的加工处理。Liao等[9]研究表明,原料挤压和蒸汽调质均显著降低了颗粒饲料的粉化率。膨化是有效去除大豆抗营养因子的加工方法,可实现抗营养抑制、蛋白质变性、微生物灭活和破坏有毒物质[23]。其特点在于原料受到强烈的机械剪切的过程使淀粉糊化、蛋白质变性和抗营养物质失活[24]。本试验结果表明,与普通豆粕相比,豆粕经膨化后颗粒饲料硬度显著提高,容重显著降低,这与孙杰[25]将豆粕膨化后低温制粒,能够提高断奶仔猪颗粒饲料加工品质的结果不同,这与颗粒饲料的加工质量可能也受到豆粕粉碎粒度的影响有关[26]。结果不同的原因可能还因为制粒膨化的方法不同,Liao等[9]和孙杰[25]是将粉料整体膨化后制粒,而本试验是单独将豆粕膨化制粒,以排除饲料中其他物质产生的影响。有关豆粕经酶解后对颗粒饲料加工品质的影响尚未见报道。本试验结果发现,与10%普通豆粕相比,添加5%的酶解豆粕显著提高了颗粒饲料硬度,显著降低了粉化率;但使用10%的酶解豆粕在提高颗粒饲料容重的同时,却增大了粉化率,影响原因较为复杂,可能是豆粕全部酶解后,蛋白质被降解为小肽,影响了颗粒硬度和稳定性。

3.2 豆粕不同加工工艺对肉兔养分表观消化率的影响Liao等[9]研究发现,膨化饲料颗粒提高了肉兔对饲粮中DM、总能、粗纤维(CF)、NDF和ADF的表观消化率。Rojas等[8]报道,饲喂膨化饲粮显著提高了育肥猪对淀粉和必需氨基酸的回肠表观消化率。程慧等[27]通过延长膨化后的热处理时间来达到降低抗营养因子目的。可见,膨化豆粕提高了动物的养分表观消化率。酶解是通过酶工艺将蛋白质原料中部分大分子蛋白质降解成活性小分子肽和游离氨基酸[28]。Ma等[29]研究表明,与金霉素阳性对照组相比,饲粮添加7.5%和9.0%的酶解豆粕,提高了断奶仔猪的生长性能,改善了抗氧化能力、免疫力和肠道屏障功能,降低了腹泻率。研究表明,酶解对动物消化性能的影响主要体现在全肠和后肠表观消化率上,如在肉鸡饲粮中添加微生物蛋白酶可使蛋白质和赖氨酸的回肠表观消化率和标准回肠消化率略有提高[30]。Park等[31]发现添加0.02%蛋白酶显著提高了猪对饲粮中DM、CP和能量的回肠表观消化率;Borda-Molina等[32]的研究也证实了此结论。本试验研究表明,膨化和酶解豆粕均能显著提高肉兔饲粮总能和CP的表观消化率,添加5%的酶解豆粕显著提高了肉兔对NDF和ADF的表观消化率,这与上述报道结果基本一致。另外,Mahmood等[33]发现利用酶解法添加多种特异性酶来去除热稳定性抗营养因子可改变肠道的pH,优化肠道菌群结构,起到稳定肠道环境的作用;而孙海涛等[34]发现添加发酵豆粕能显著促进伊拉肉兔的肠道发育和改善盲肠菌群。

3.3 豆粕不同加工工艺对肉兔血清免疫指标的影响豆粕加工工艺引起免疫相关指标差异的主要原因是大豆中致敏蛋白的去除程度不同。本试验中,肉兔血清总蛋白含量为50~80 g/L,血清白蛋白含量为35~50 g/L,血清球蛋白含量为15~35 g/L,都在正常范围内。本试验中,添加酶解豆粕组肉兔血清总蛋白、球蛋白和白蛋白含量都较低;添加膨化豆粕组肉兔血清免疫球蛋白含量较高。膨化豆粕使肉兔血清C4含量显著升高,表明肉兔非特异性免疫增强。膨化和酶解都能去除致敏蛋白,减少免疫反应,且酶解去除得更彻底,这与孙培鑫等[35]研究结果相似。但Wang等[36]认为血清免疫球蛋白不受蛋白质水平和补充角蛋白酶的影响,原因可能是添加蛋白酶的种类和剂量不同。Lu等[37]研究表明,添加膨化豆粕显著提高了生长育肥猪猪血清IgG和IgM含量;Zhu等[38]发现膨化豆粕显著提高了断奶仔猪血清IgG、IgM和IgA含量。本试验中,膨化豆粕饲喂肉兔有类似效果;但是添加酶解豆粕组肉兔血清IgA和IgG含量较低,可能是因为酶解使大豆抗营养因子含量降低,从而降低了肉兔的免疫反应。

4 结论① 饲粮添加5%普通豆粕+5%酶解豆粕能够提高肉兔颗粒饲料硬度,降低粉化率,从而提高颗粒饲料加工品质;同时,还能提高肉兔对饲粮CP、NDF和ADF的表观消化率,降低肉兔免疫反应。

② 饲粮添加10%酶解豆粕和10%膨化豆粕能够提高肉兔对饲粮总能的表观消化率。

③ 本试验条件下,推荐肉兔饲粮中使用5%普通豆粕+5%酶解豆粕。

| [1] |

游金明, 李德发. 大豆抗营养因子研究进展[J]. 饲料与畜牧, 2006(9): 40-43. YOU J M, LI D F. Research progress of anti-nutrient factors in soybean[J]. Feed and Husbandry, 2006(9): 40-43 (in Chinese). DOI:10.3969/j.issn.1006-6314-B.2006.09.005 |

| [2] |

L'ANSON K A, CHOCT M, BROOKS P H, et al. Effect of feed processing and enzyme supplementation on diet digestibility and performance of male weaner pigs fed wheat-based diets in dry or liquid form[J]. Animal Production Science, 2013, 53(6): 531-539. DOI:10.1071/AN12256 |

| [3] |

孙常灿, 何晓丽, 杨容, 等. 大豆胰蛋白酶抑制剂微生物发酵灭活研究[J]. 畜禽业, 2007(6): 50-52. SUN C C, HE X L, YANG R, et al. Inactivation of soybean trypsin inhibitor by fermentation with microoganism[J]. Livestock and Poultry Industry, 2007(6): 50-52 (in Chinese). DOI:10.3969/j.issn.1008-0414.2007.06.032 |

| [4] |

丁小玲, 李吕木, 许发芝, 等. 固态发酵菜籽粕替代膨化豆粕对断奶仔猪生长性能及血清生化指标的影响[J]. 中国农业大学学报, 2011, 16(4): 107-112. DING X L, LI L M, XU F Z, et al. Effects of solid-state fermented rapeseed meal replacing expanding soybean meal on the growth performance and the blood biochemical parameters in weaned piglets[J]. Journal of China Agricultural University, 2011, 16(4): 107-112 (in Chinese). |

| [5] |

徐学明, 刘亚军. 热处理全脂大豆的品质评价[J]. 饲料与畜牧, 2006(8): 29-31. XU X M, LIU Y J. Quality evaluation of heat-treated full-fat soybean[J]. Feed and Husbandry, 2006(8): 29-31 (in Chinese). DOI:10.3969/j.issn.1006-6314-B.2006.08.013 |

| [6] |

STEIN H H, SÈVE B, FULLER M F, et al. Invited review: amino acid bioavailability and digestibility in pig feed ingredients: terminology and application[J]. Journal of Animal Science, 2007, 85(1): 172-180. DOI:10.2527/jas.2005-742 |

| [7] |

HTOO J K, MENG X, PATIENCE J F, et al. Effects of coextrusion of flaxseed and field pea on the digestibility of energy, ether extract, fatty acids, protein, and amino acids in grower-finisher pigs[J]. Journal of Animal Science, 2008, 86(11): 2942-2951. DOI:10.2527/jas.2007-0313 |

| [8] |

ROJAS O J, VINYETA E, STEIN H H. Effects of pelleting, extrusion, or extrusion and pelleting on energy and nutrient digestibility in diets containing different levels of fiber and fed to growing pigs[J]. Journal of Animal Science, 2016, 94(5): 1951-1960. DOI:10.2527/jas.2015-0137 |

| [9] |

LIAO K Y, CAI J Y, SHI Z J, et al. Effects of raw material extrusion and steam conditioning on feed pellet quality and nutrient digestibility of growing meat rabbits[J]. Animal Nutrition, 2017, 3(2): 151-155. DOI:10.1016/j.aninu.2017.03.006 |

| [10] |

PLAHAR W A, OKEZIE B O, GYATO C K. Development of a high protein weaning food by extrusion cooking using peanuts, maize and soybeans[J]. Plant Foods for Human Nutrition, 2003, 58(3): 1-12. |

| [11] |

OMOHIMI C I, SOBUKOLA O P, SARAFADEEN K O, et al. Effect of process parameters on the proximate composition, functional and sensory properties[J]. International Journal of Nutrition and Food Engineering, 2013, 7(4): 269-271. |

| [12] |

PETTEY L A, CARTER S D, SENNE B W, et al. Effects of beta-mannanase addition to corn-soybean meal diets on growth performance, carcass traits, and nutrient digestibility of weanling and growing-finishing pigs[J]. Journal of Animal Science, 2002, 80(4): 1012-1019. DOI:10.2527/2002.8041012x |

| [13] |

OMOGBENIGUN F O, NYACHOTI C M, SLOMINSKI B A. Dietary supplementation with multienzyme preparations improves nutrient utilization and growth performance in weaned pigs[J]. Journal of Animal Science, 2004, 82(4): 1053-1061. DOI:10.2527/2004.8241053x |

| [14] |

KIM S W, ZHANG J H, SOLTWEDEL K T, et al. Use of carbohydrases in corn-soybean meal based grower-finisher pig diets[J]. Animal Research, 2006, 55(6): 563-578. DOI:10.1051/animres:2006039 |

| [15] |

龚阿琼, 高震, 陈敬帮, 等. 不同酶制剂对豆粕中抗原蛋白的影响[J]. 中国饲料, 2019(23): 120-123. GONG A Q, GAO Z, CHEN J B, et al. The influence of different enzyme preparation of antigen protein in soybean meal[J]. China Feed, 2019(23): 120-123 (in Chinese). DOI:10.15906/j.cnki.cn11-2975/s.20192328 |

| [16] |

魏凤仙, 高方, 李绍钰, 等. 膨化法与微生物发酵处理法对豆粕营养价值的影响[J]. 河南农业科学, 2014, 43(4): 123-127. WEI F X, GAO F, LI S Y, et al. Effects of extrusion and fermentation treatment methods on nutritional value of soybean meal[J]. Journal of Henan Agricultural Sciences, 2014, 43(4): 123-127 (in Chinese). DOI:10.3969/j.issn.1004-3268.2014.04.027 |

| [17] |

魏金涛, 赵娜, 李绍章, 等. 复合酶酶解豆粕营养成分变化规律研究[J]. 中国粮油学报, 2014, 29(1): 17-20, 25. WEI J T, ZHAO N, LI S Z, et al. Influence of complex enzyme enzymolysis on the nutrient contents of soybean meal[J]. Journal of the Chinese Cereals and Oils Association, 2014, 29(1): 17-20, 25 (in Chinese). |

| [18] |

李福昌. 家兔营养[M]. 北京: 中国农业出版社, 2009: 167-170. LI F C. Nutrition of the rabbit[M]. Beijing: China Agriculture Press, 2009: 167-170 (in Chinese). |

| [19] |

张丽英. 饲料分析及饲料质量检测技术[M]. 4版. 北京: 中国农业大学出版社, 2016: 260-261. ZHANG L Y. Feed analysis and quality test technology[M]. 4th ed. Beijing: China Agricultural University Press, 2016: 260-261 (in Chinese). |

| [20] |

陶丽娟, 张艳春, 李建涛, 等. 玉米胚芽粕对肉仔鸡的代谢能和回肠氨基酸表观消化率的测定[J]. 沈阳农业大学学报, 2020, 51(6): 741-746. TAO L J, ZHANG Y C, LI J T, et al. Determination of metabolic energy and apparent digestibility of amino acids in ileum of corn germ meal in broilers[J]. Journal of Shenyang Agricultural University, 2020, 51(6): 741-746 (in Chinese). |

| [21] |

BEHNKE K C. Feed manufacturing technology: current issues and challenges[J]. Animal Feed Science and Technology, 1996, 62(1): 49-57. DOI:10.1016/S0377-8401(96)01005-X |

| [22] |

ACEDO-RICO J, MÉNDEZ J, SANTOM G. Feed manufacturing[M]//BLAS C D, WISEMAN J. Nutrition of the rabbit. 2nd ed. Cambridge: CABI, 2010.

|

| [23] |

ANUONYE J C, JIGAM A A, NDACEKO G M. Effects of extrusion-cooking on the nutrient and anti-nutrient composition of pigeon pea and unripe plantain blends[J]. Journal of Applied Pharmaceutical Science, 2012, 2(5): 158-162. |

| [24] |

MARTÍN-CABREJAS M A, JAIME L, KARANJA C, et al. Modifications to physicochemical and nutritional properties of hard-to-cook beans (Phaseolus vulgaris L.) by extrusion cooking[J]. Journal of Agricultural and Food Chemistry, 1999, 47(3): 1174-1182. DOI:10.1021/jf980850m |

| [25] |

孙杰. 断奶仔猪颗粒料加工工艺比较研究[D]. 硕士学位论文. 北京: 中国农业科学院, 2014. SUN J. Comparative studies of the different processing technologies on the weaned piglet's feed pellet[D]. Master's Thesis. Beijing: Chinese Academy of Agricultural Sciences, 2014. (in Chinese) |

| [26] |

赵丹阳, 李军国, 秦玉昌, 等. 玉米和豆粕不同粉碎粒度组合对颗粒加工质量和肉鸡生长性能的影响[J]. 动物营养学报, 2019, 31(10): 4553-4562. ZHAO D Y, LI J G, QIN Y C, et al. Effects of different crushing particle size combination of corn and soybean meal on processing quality of granules and growth performance of broilers[J]. Chinese Journal of Animal Nutrition, 2019, 31(10): 4553-4562 (in Chinese). |

| [27] |

程慧, 王梅, 杨振才. 膨化大豆的保温时间对抗营养因子和蛋白质溶解度的影响[J]. 中国饲料, 2020(11): 7-10. CHENG H, WANG M, YANG Z C. The effect of heat preservation time of expanded soybean on nutrient factor and protein solubility[J]. China Feed, 2020(11): 7-10 (in Chinese). DOI:10.15906/j.cnki.cn11-2975/s.20201102 |

| [28] |

王诗琦, 陈雪娇, 梁丽萍, 等. 饲粮添加酶解蛋白肽对断奶仔猪生长性能、血清免疫指标和肠道菌群的影响[J]. 动物营养学报, 2022, 34(2): 839-851. WANG S Q, CHEN X J, LIANG L P, et al. Effects of dietary enzymatic protein peptide on growth performance, serum immune indices and intestinal flora of weaned piglets[J]. Chinese Journal of Animal Nutrition, 2022, 34(2): 839-851 (in Chinese). |

| [29] |

MA X K, SHANG Q H, WANG Q Q, et al. Comparative effects of enzymolytic soybean meal and antibiotics in diets on growth performance, antioxidant capacity, immunity, and intestinal barrier function in weaned pigs[J]. Animal Feed Science and Technology, 2019, 248: 47-58. DOI:10.1016/j.anifeedsci.2018.12.003 |

| [30] |

ERDAW M M, PEREZ-MALDONADO R A, IJI P A. Apparent and standardized ileal nutrient digestibility of broiler diets containing varying levels of raw full-fat soybean and microbial protease[J]. Journal of Animal Science and Technology, 2017, 59: 23. DOI:10.1186/s40781-017-0148-2 |

| [31] |

PARK S, LEE J J, YANG B M, et al. Dietary protease improves growth performance, nutrient digestibility, and intestinal morphology of weaned pigs[J]. Journal of Animal Science and Technology, 2020, 62(1): 21-30. DOI:10.5187/jast.2020.62.1.21 |

| [32] |

BORDA-MOLINA D, ZUBER T, SIEGERT W, et al. Effects of protease and phytase supplements on small intestinal microbiota and amino acid digestibility in broiler chickens[J]. Poultry Science, 2019, 98(7): 2906-2918. DOI:10.3382/ps/pez038 |

| [33] |

MAHMOOD T, MIRZA M A, NAWAZ H, et al. Effect of different exogenous proteases on growth performance, nutrient digestibility, and carcass response in broiler chickens fed poultry by-product meal-based diets[J]. Livestock Science, 2017, 200: 71-75. DOI:10.1016/j.livsci.2017.04.009 |

| [34] |

孙海涛, 杨丽萍, 姜文学, 等. 发酵豆粕对断奶~2月龄肉兔生长发育、血清生化及肠道发育的影响[J]. 山东农业科学, 2017, 49(8): 131-135. SUN H T, YANG L P, JIANG W X, et al. Effects of fermented soybean meal on growth performance, serum biochemistry and intestinal development of weaner to two-month-old growing meat rabbits[J]. Shandong Agricultural Sciences, 2017, 49(8): 131-135 (in Chinese). DOI:10.14083/j.issn.1001-4942.2017.08.031 |

| [35] |

孙培鑫, 陈代文, 余冰, 等. 去皮膨化豆粕对早期断奶仔猪免疫机能和血液生化指标的影响[J]. 饲料工业, 2007, 28(15): 31-35. SUN P X, CHEN D W, YU B, et al. Effect of flay extruded soybean meal on immune function and biochemical indicators in serum of piglets[J]. Feed Industry, 2007, 28(15): 31-35 (in Chinese). DOI:10.3969/j.issn.1001-991X.2007.15.011 |

| [36] |

WANG D, ZENG Z K, PIAO X S, et al. Effects of keratinase supplementation of corn-soybean meal based diets on apparent ileal amino acid digestibility in growing pigs and serum amino acids, cytokines, immunoglobulin levels and loin muscle area in nursery pigs[J]. Archives of Animal Nutrition, 2011, 65(4): 290-302. DOI:10.1080/1745039X.2011.586140 |

| [37] |

LU J F, ZHANG X Y, LIU Y H, et al. Effect of fermented corn-soybean meal on serum immunity, the expression of genes related to gut immunity, gut microbiota, and bacterial metabolites in grower-finisher pigs[J]. Frontiers in Microbiology, 2019, 10: 2620. DOI:10.3389/fmicb.2019.02620 |

| [38] |

ZHU J J, GAO M X, ZHANG R L, et al. Effects of soybean meal fermented by L. plantarum, B. subtilis and S. cerevisieae on growth, immune function and intestinal morphology in weaned piglets[J]. Microbial Cell Factories, 2017, 16(1): 191. DOI:10.1186/s12934-017-0809-3 |